CNC Machining, Fabrication and Welding, Large Runs or Prototypes.

Call today! 918-687-3077

Click here to contact us for a free quote

CNC Machining Services

With several CNC lathes, CNC mills and other machine capabilities, Muskogee Manufacturing can manage large or small parts and quantities. We have ample experience working with steel, stainless steel, aluminum, brass, all types of plastic and rubber.

Equipment List:

- Daewoo Puma 2500 SY CNC Lathe

- Mazak Super Quick Turn 15M Mark II CNC Lathe

- Mazak Quick Turn 6T CNC Lathe

- Haas TM1 CNC Vertical Mill

- Fadal VMC15XT Vertical Machine Center

- Clausing Metosa C1440 Lathe

- Bridgeport Vertical Mill - 2

- Supermax Vertical Mill

- Gear Hob

- Dake 'H' Frame Shop Press

- Metal Brake

- Media Blasting Cabinet

- Parts Cleaning Station

- Paint Booth

- Solder Machine

- Vertical Band Saw

- Horizontal Band Saw

Machinery

Haas TM1 CNC Vertical Mill

Mazak Super Quick Turn 15M Mark II CNC Lathe

Clausing Metosa C1440 Lathe

Daewoo Puma 2500 SY CNC Lathe

Examples

Muskogee Manufacturing routinely makes runs of several hundred parts. Our machining processes are highly efficient which reduces cost and shortens production time. Our specialty is machining parts from bar stock to make use of our automated bar feed setup whenever possible.

These plastic parts were machined from 2.5" PVC rod using our Daewoo Puma 2500SY with automatic bar feed and sub spindle. This allows us to create a finished part without any intervention such as placing a blank in the chuck, turning the part over in the chuck or any post lathe operations.

Other Processes

Muskogee Manufacturing works with many other manufacturing specialists to complete parts or projects with special requirements. Some of these processes include:

- Rubber Molding

- Plastic Molding

- Sand Casting

- Investment Casting

- Metal Spinning

- Laser Cutting

- Powder Coating

- Aluminum Anodizing

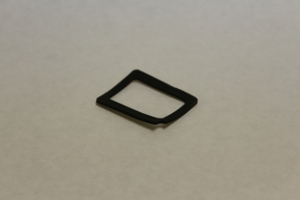

This part was designed, machined and welded by Muskogee Manufacturing. A blank was ordered from a metal spinner and the part was powder coated after completion.

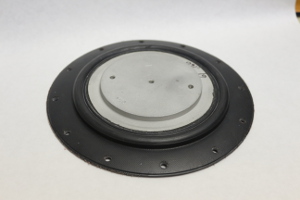

This rubber diaphragm with an aluminum insert was designed by Muskogee Manufacturing. MM machines the metal insert then sends it to be molded using compression rubber molds that were also manufactured by Muskogee Manufacturing. The diaphragm then has the bolt pattern cut using a steel rule die and our clicker press.

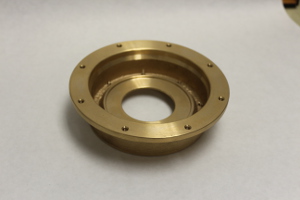

Muskogee Manufacturing has decades of experience working with metal castings. This brass cylinder was designed by Muskogee Manufacturing. MM receives the part as a brass casting and machines the part using our lathe into a finished product. Processes used include turning, drilling and tapping.

These brass flanges were designed by Muskogee Manufacturing. The flange is machined and used as a component in a chemical pump.